In-Motion weighing checkweighers and industrial metal detection systems offer a broad selection of features and options to maximize efficiency.

Checkweighers

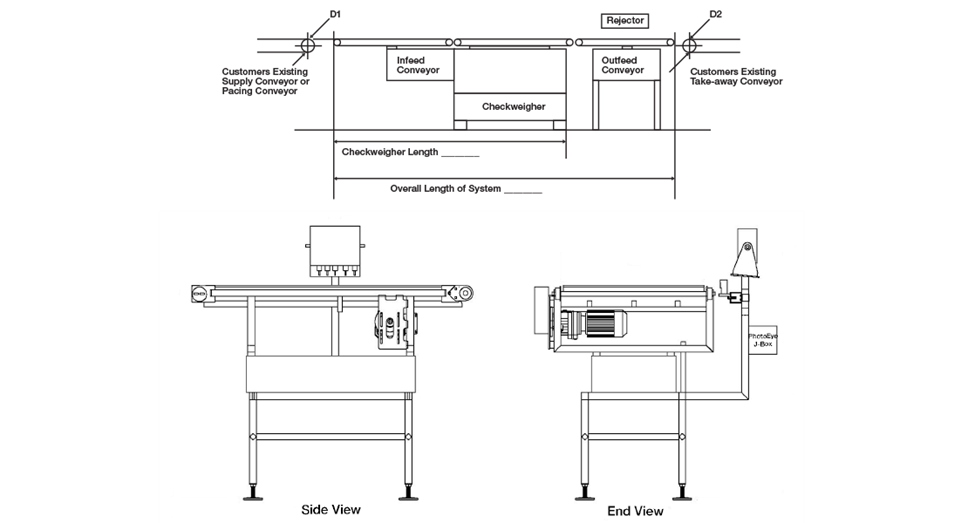

For individual products, get quick, in-motion verification of a targeted weight range. Create up to four lanes of operation customized with bar code verification or reject systems. For product up to 200 pounds, non-Legal for Trade systems are available with a resolution as precise as one gram, at speeds up to 80 units per minute.

Conveyor Scales

For individual product labeling or weight-data capture, conveyor scales are designed to send weight data to peripheral devices such as PCs, printers and weigh price labelers. MotoWeigh conveyor scales offer Legal for Trade accuracy at up to 60 units per minute and 2000 divisions.

Construction: Configurations: Speed: | Container Types: Belts: Power Configuration: | Checkweigher Packages: Checkweigher Packages Include: |

- Password protected user logins

- Real-time statistical information

- Product report

- Statistical report

- Parameter report

- User report

- Store up to 1,000 different products

- Five-zone classification

- 1280 controller

- Power disconnect with lock-out/tag-out

- E-stop

- VFD (variable frequency drive)

- Motor overloads

- Square tube construction (SST or aluminum)

- 32 in height from top of belt with ± 2.5 in of adjustment

- Modular belting

- Divert methods:

- Pneumatic pusher

- Air blast

- Drop conveyor

- Paddle

- Secondary diverter in series or parallel

- One-, three- or five-zone communication tower

- Audible alarm (non-washdown only)

- Draft shields

- Drop chutes

- Pull cord E-stops

- Portability package (non-NTEP Certified only)

- Conveyor guide rails (round or flat)

- Custom programming available

- Food-grade SST angle construction, NEMA Type 4X IP66 washdown systems

- Meets HACCP requirements

- UL 508

- NTEP Certified Legal for Trade (up to 2,000 divisions and 60 ppm)

- Pacing conveyor